- Home

- Knowledge Base

- Production Planning

- Production Planning Materials

Production Planning Materials

- Production planning is activated per Transaction Type on the Settings tab.

- Organisations with multiple departments or processes, can create multiple Work Order Transaction Types and activate production planning for each one.

- Each Work Order Transaction Type has its own production planning board.

- A single Work Order can contain multiple items that must be produced. The production planning module separates the jobs and tasks for each item that is part of an estimate.

- The expected transaction flow is Quotation > Sales Order > Work Order. However, work orders may be created directly.

- Behind the scenes, planning fields are integrated into the materials and routing sections (tasks and outwork) of estimates.

- As part of the Work Order Menu options, production views are used to manage outwork, materials, services, and timekeeping.

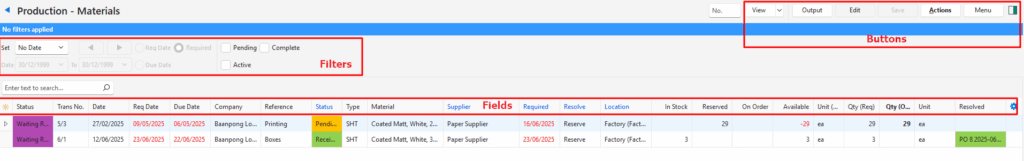

The Materials View displays the materials that are needed for the jobs currently in production.

Fields with blue captions may be edited.

The navigation depends on where you added Work Orders to your menu.

Navigation: … Work Orders > Menu (button) > Materials

List View Materials

Buttons Explained

| Button | Description |

|---|---|

| View | Generates a list of entries as per the selected data filters. |

| Arrow on View Button | Reset Data Filter: Resets all the data filters. |

| Output | Prints, previews, or exports the selected report if Output Templates are added. Exports the current display in .xlsx format. |

| Edit | Allows Users to edit the entry. |

| Actions | Allows for changes to be made to multiple records that can be selected using Ctrl Left Click. The options are: Batch Update: Changes all the selected records when Update (button) is clicked. The options are: – Location: Sets the location to the one selected from the dropdown list. – Required: Sets the required date (for the materials) to the one selected on the calendar. – Resolve: Sets the resolve option to the one selected from the dropdown list. The options are Purchase or Reserve. If Purchase is set, any inventory location is cleared. – Status: Sets the status of the Item to the one selected from the dropdown list. – Supplier: Sets the supplier to the one selected from the dropdown list. Copy to Purchase Orders: Materials: Creates a Purchase Order. (Text may vary. It is the copy command created under Copy Rules.) Multiple records may be selected. Multiple items can be selected. If the items belong to different Suppliers, or no supplier is filled in, an error is returned. Whether or not the purchase order is opened depends on the Copy Rules setting. Copy to Goods Issued: Creates a Goods Issued. (Text may vary. It is the copy command created under Copy Rules.) Multiple records may be selected. |

| Menu | Settings – User Access – Edit Transaction Type Views – Transaction – Transactions – Items Views – Production – Jobs – Materials – Tasks – Outwork Layout |

Filters Explained

| Filter | Description |

|---|---|

| Set | A dropdown list with date options (e.g. No Date, Today, This Year). |

| ← → | Adjusts the Date in the direction of the arrow. |

| Date … to … | Allows users to set their own Dates (based on the selection under Set). |

| Due Date (radio button) | Applies the selected date to filter the records according to their Due Dates (the job’s due date as per the transaction). |

| Req Date (radio button) | Applies the selected date to filter the records according to their Required Dates (the job’s required date as per the transaction). |

| Required (radio button) | Applies the selected date to filter the records according to when they are required (when the material is required). |

| Pending (checkbox) | Filters the view to show Pending jobs. |

| Active (checkbox) | Filters the view to show Active jobs. |

| Completed (checkbox) | Filters the view to show Complete jobs. |

Fields Explained

| Field | Description |

|---|---|

| ID | The system-generated number for the entry. |

| TransItem ID | The system-generated number of the transaction item. |

| Trans ID | The system-generated number for the transaction. |

| Trans ID (Resolved) | The system-generated number for the resolve transaction. |

| Status (Status Trans) | The Status of the Transaction. |

| Trans No. | The transaction and item number. |

| Date | The Transaction Date. |

| Req Date | The Required Date. If the date is before today, it is shown in red. – Required dates are typically used to indicate the date by which the customer requires the goods. – Captions may vary because they are set when creating Transaction Types. |

| Due Date | The Due Date. – This date is shown in red if it is later than the required date. – Due dates are typically used to indicate when the goods must be ready. – Captions may vary because they are set when creating Transaction Types. |

| Company | The name of the Customer or Supplier. |

| Reference | The reference typed on the transaction. |

| Product | The name of the product. |

| Status (Item) | The Status of the Item. |

| Status (Status Mat) | The Status of the Material. – This status is used to calculate the Materials % complete on the Jobs view. – Statuses are created here: Edit Transaction Type (e.g. Work Order) > Menu (button) > Edit Statuses (Production Materials). |

| Type | The type of item. |

| Material | The name of the material. |

| Supplier | The name of the supplier if the material is purchased. |

| Required (Date Req (Mat)) | The date on which the material is required. |

| Resolve | The material item’s Resolve. These options are specific to the production module and are not the resolve options selected for the transaction type. If the material is an inventory item, the resolve is automatically set to Purchase. Else it is set to Reserve. |

| Location | The location for the material item. – There is a dropdown list of locations if the item has Fixed or All Locations selected next to Inventory (Item Header). – If the item is not a material item, or N/A was selected next to Inventory, a location cannot be selected. – If a default location was selected for transaction type, it is automatically filled in. (Default > Inventory Location (Production Materials)) – If the material item only has one Fixed Location, it is selected by default, and no other location can be selected. (This location overrides the transaction type’s default location.) |

| In Stock | The quantity that is currently in stock. |

| Reserved | The quantity that is reserved for current orders. |

| On Order | The quantity that has been ordered, but not yet received. |

| Available | The quantity that is available. |

| Unit (Stock) | The Stock Item’s Unit. |

| Qty (Req) | The quantity that is required. |

| Qty (Out) | The quantity that is still outstanding. |

| Unit | The unit of the outstanding quantity. |

| Resolved | The code, number, and date of the resolve transaction. The block is colour-coded to match the status of the purchase order. For example, if the resolve option is purchase, and you click Actions (button) > Copy to Purchase Order, this field shows PO for Purchase Order, the number of the purchase order and the date on which the purchase order was created. This purchase order is thereafter referred to as the resolve transaction. |

| Created | The date on which the entry was created. |

| Updated | The date on which the entry was updated. |

| Updated By | The User who last updated the entry. |

| Widget | A submenu, which can also be accessed by right clicking the entry, with the following functions: – Open Transaction: Opens the related work order. – Open Resolve Transaction: See explanation next to Resolved. Opens the resolve transaction if there is one. – Open Linked Item: Opens the linked item. – View Item Summary: Displays the item summary on the right. – Copy to Purchase Orders: Materials: Creates a purchase order to purchase materials that have the resolve Purchase. |

Production Materials Tutorials

These tutorials explain how to use the various functions available for Production – Materials.

How to Edit Individual Material Entries

- Navigate to Work Orders.

- Click Menu (button) > Materials.

- Set the filters as needed.

- Click View (button).

- Click Edit (button).

- Click any of the fields in the column with blue captions and select alternate options from the dropdown lists, calendars or time choosers.

- Click Save (button).

How to Edit Multiple Entries (Batch Updates)

- Navigate to Work Orders.

- Click Menu (button) > Materials.

- Set the Date and Status filters as needed.

- Click View (button).

- Click Actions(button) > Batch Update.

- Select the entries you want to change. (Use Ctrl Left click to multi-select.)

- Select one of these options next to Update:

- Location: Select a location from the adjacent dropdown list.

- Required: Select a date from the adjacent calendar (sets the date on which the materials are required).

- Resolve: Select a resolve option from the adjacent dropdown list.

- Note: The dropdown list contains all the resolve options selected for the Transaction Type.

- Status: Select a status from the adjacent dropdown list.

- Supplier: Select a supplier from the adjacent dropdown list.

- Click Update (button).

- Confirm the change.

How to Create a Resolve Transaction

The required date shown on the Purchase Order is the required date on the first selected item (i.e. the date entered on the Required column next to Supplier).

- Navigate to Work Orders.

- Click Menu (button) > Materials.

- Set the filters as needed.

- Click View (button).

- Click the entry or entries you want to create a transaction for. (Use Ctrl Left click to multi select).

- Note: If the supplier field is blank, or the items are purchased from different suppliers, the purchase order is not created.

- Click Actions (button) > Copy to Purchase Orders: Materials.

- Note: The description might have different wording (it is the user-provided caption for the Copy Rule).

- If successful, the Purchase Order Number and Date is displayed in the Resolve column.

- Note: Whether the purchase order is opened or not depends on the copy rules.

How to Open the Resolve Transaction

- Navigate to Work Orders.

- Click Menu (button) > Materials.

- Set the filters as needed.

- Click View (button).

- Right click an entry that has a transaction number and date under the Resolve column and select Open Resolve Transaction from the context menu.

- Note: If there is no data in the Resolve column, a resolve transaction has not yet been created.

How to View a Linked Item

- Navigate to Work Orders.

- Click Menu (button) > Materials.

- Set the filters as needed.

- Click View (button).

- Right click an entry and select Open Linked Item from the context menu.

- Note: The item is opened on a popup and can be edited. However, the popup does not provide for general item-related functions such as creating new items.

How to View an Item Summary

- Navigate to Work Orders.

- Click Menu (button) > Materials.

- Right click an entry and select View Item Summary from the context menu.

- If the particular entry is an item (as opposed to a custom entry), the summary is opened on the right.

How to View the Work Order Transaction

- Navigate to Work Orders.

- Click Menu (button) > Materials.

- Set the filters as needed.

- Click View (button).

- Right click an entry and select Open Transaction from the context menu.

- The Work Order is opened.

- Note: Use the navigational arrow next to the text Edit Work Orders to return to the Materials production view.